Introduction

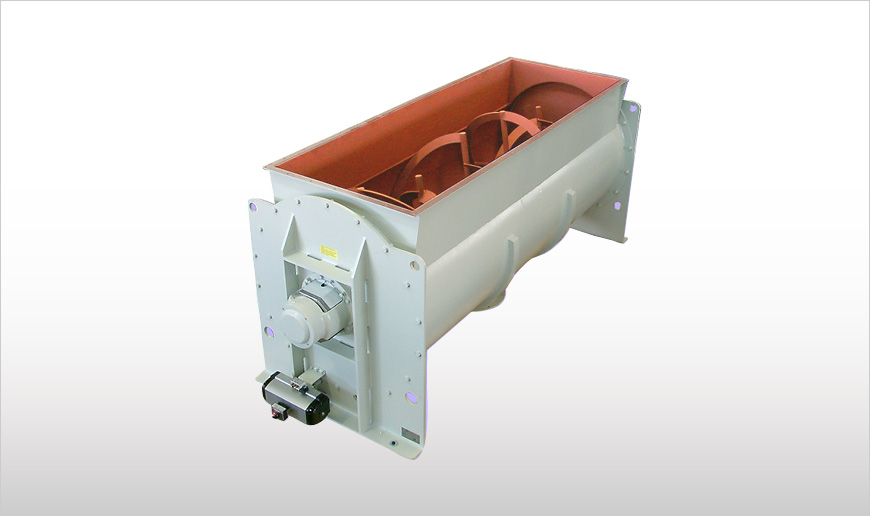

The WBN Batch-Type Ribbon Blender, with its slowly turning single shaft double counter-pitch ribbon screw, is the ideal machine to obtain high quality mixtures with fragile materials, at the same time conserving the physical properties of the product.

Gentle product treatment, no damage of the product

Excellent reproducibility of batches

Technical Specs

Description

Batch-type WBN Ribbon Blenders consist of a horizontal, single shaft double counter-pitch ribbon screw housed in a tubular mixing drum, a central inlet or a rectangular shape inlet port over the entire length of the mixing drum, an outlet with central discharge outlet, a venting spout, two drum closing end plates complete with integrated air or gas-purged shaft seals, and a drive unit complete with power transmission.

Function

The outer helix moves the material from both ends of the vessel towards the centre, while the inner helix transfers the material towards both ends, performing a sort of convective mixing. The product is gently processed in a relatively short mixing time.

Typically Batch-type WBN Ribbon Blenders are used for mixing dry PVC, dry powders or granules in general, as well as liquids and low-viscosity pastes.

Features

- Capacity: 10 ~ 20,000 litres per batch

- Mixing time: 5 ~ 15 min

- End bearing assemblies with various types of air or nitrogen-purged shaft seals or grease sealing

- Heavy-duty mixing chamber manufactured from carbon steel or 304L / 316L stainless steel

- Stainless steel surface finish: grit silking, mirror polishing, glass bead blasting

- Large hopper inlet or multiple round inlet spouts

Benefits

- Low maintenance

- Durable machine

- Power rating adapted to application

- Mixing know-how and test facilities

Options

- Equipment for additional liquid supply

- Pneumatic sampling device

- Pneumatic control panel

- Jacketed mixing chamber for heating or cooling