Introduction

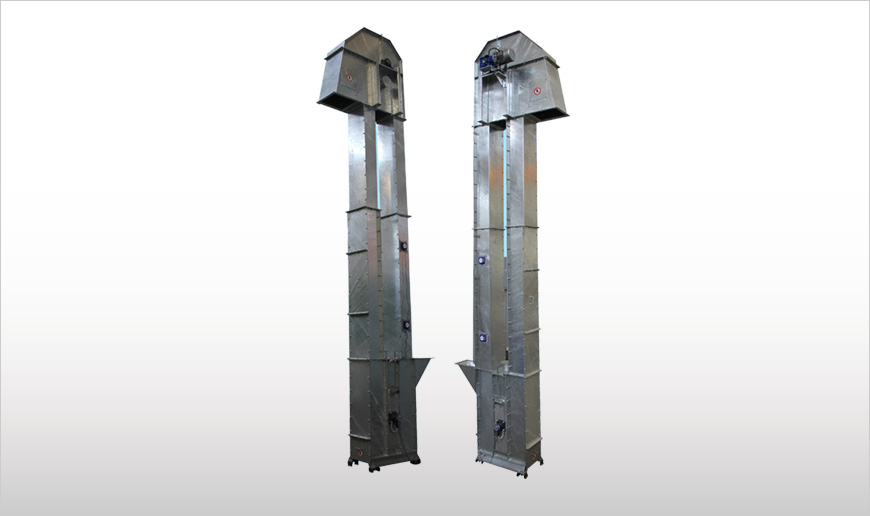

EI-type Bucket Elevators are the ideal solution for vertical elevation of fine aggregates and minerals. They are especially designed to operate at low speed and are manufactured from standardised modular components.

Easy on site assembly and maintenance

Technical Specs

Description

EI-type Bucket Elevators are specialised for vertical elevation of fine aggregates and minerals. They are designed to operate at low speed and are manufactured from hot-galvanized carbon steel. The machines consist of a head and a foot section which include solidly mounted roller bearings as support for the bucket carrier belt, a variable number of trunkings, an intermediate trunking section for bucket assembly and inspection, along with all the other intermediate casings. The particular design of the buckets manufactured from abrasion-resistant Nylon PA6, or mild steel, offers extended durability versus abrasive materials handled.

The wide range of options and accessories enable a great variety of applications of EI-type Bucket Elevators providing highly efficient state-of-the-art performance in compliance with the relevant standards.

Function

EI-type Bucket Elevators are used for vertical elevation of fine aggregates such as carbonate, lime, limestone, sand, minerals and similar materials dry, powdery, abrasive, non packing materials having particle size of up to 5 mm.

Material is introduced into a loading hopper which is included in the foot section. There the material is continuously picked up by appropriately shaped buckets which are fixed at an equal distance to an endless belt that rotates around a foot and a head roller wheel. The buckets are discharged through an outlet spout in the head section by centrifugal force after having passed the upper roller wheel. EI Bucket Elevators are used in material handling and storage plants, as well as in different types of material processing plants.

EI Bucket Elevators are used in handling and storage plants, dry building material processing plants, asphalt plants, ceramics processing, the chemical and petrochemical industry.

Features

- Throughput rates up to 191 m3/h (112cfm)

- Discharge height up to 44 metres (144 ft)

- Surface treatment: hot dip galvanized

- Direct gear motor

- Inspection hatches on head and foot section

- Rotation and belt misalignment sensors

- ATEX versions on requests

- Version completely in stainless steel on request

Benefits

- Easy on site assembly and maintenance

- Reliable in operation

- Durable