Introduction

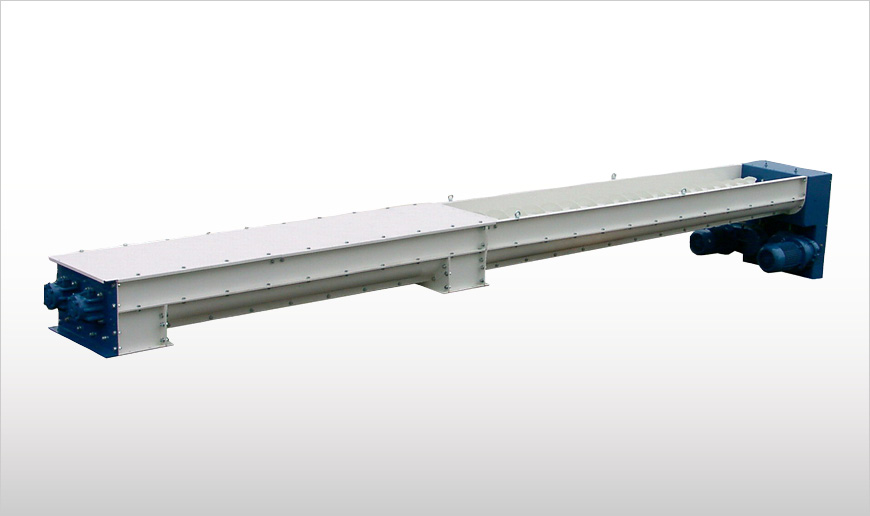

BU Twin Shaft Screw Feeders are an option for users who require particularly efficient discharging/feeding from bins or hoppers. They are designed for handling of non homogeneous materials (wood chippings, paper, etc.), materials from the flour milling industry (bran, flour, etc.), and bridging materials (e.g. sawdust, soy, etc.).

Provides constant feeding even with difficult materials

Technical Specs

Description

BU Twin Shaft Screw Feeders are equipped with a tapered inlet trough following the shape of the tapered inlet sections of the two screws, enclosing them almost completely from below at minimum clearance.

BU Screw Feeders are manufactured from carbon steel. The upper trough flange is fitted to match the outlet of the bin or hopper.

Function

BU Twin Shaft Screw Feeders are an option for users who require particularly efficient discharging/feeding from bins or hoppers. BU is designed for handling of non homogeneous materials (wood chippings, paper, etc.), materials from the flour milling industry (bran, flour, etc.), and bridging materials (e.g. sawdust, soy, etc.).

BU Screw Feeders are available with ATEX, Zone 22 certification.

Features

- Powder-coated

- Tapered square pitch screws and trough manufactured from carbon steel

- WAM standard inlet and outlet

- Maintenance-free flanged cast iron end bearing assemblies with external bearings and manually adjustable packed gland seal

- Maintenance-free intermediate hanger bearings with self-lubricating slide bushes

- Fixed or variable speed gear motors with chain transmission mounted opposite drive end

- Robust design

BU SCREW FEEDERS ARE AVAILABLE WITH ATEX, ZONE 22 CERTIFICATION.

Benefits

- Modular design enabling easy access and individual custom-design features

- Promotes mass flow

- Gives wide feeding surface

- Avoids bridging

- Avoids segregation

- Provides constant feeding even with difficult materials

- Reliable and constant feed rates

- High degree of self-cleaning of the trough