Introduction

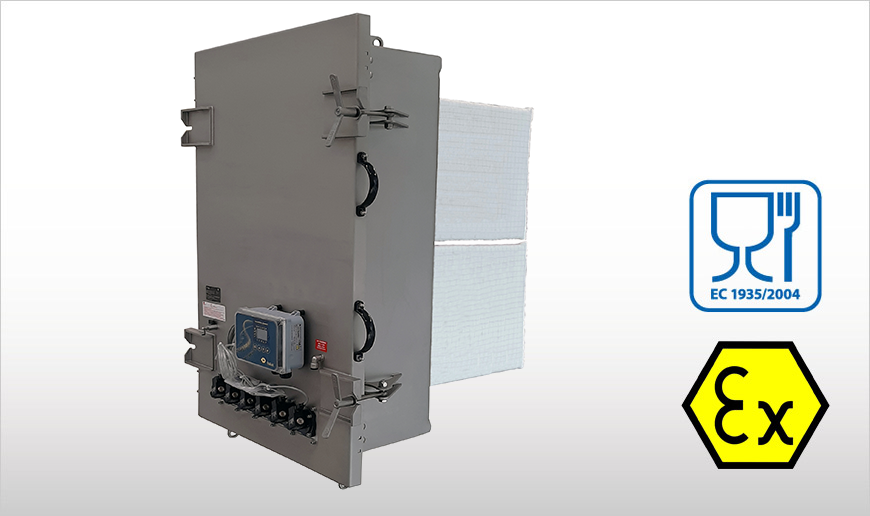

WAMAIR Vacuum FPN and FPNX are specially designed to meet the requirements of vacuum applications. They are suitable virtually for all industries. Thanks to their hygienic design and food-grade filter elements they comply with the EC 1935/2004 directive which makes them suitable for a variety of applications in food processing (wheat, beans, sugar, rice, coffee, cocoa, diet foods, chilli pepper, etc.).

FOOD and ATEX certification

Easy and quick access for cleaning

Technical Specs

Description

WAMAIR Vacuum is a polygonal Dust Collector range which comes in mild steel, or 304 / 316 stainless steel. Filter elements are inserted horizontally or vertically. A compressed air pulse-jet cleaning system is integrated into the access door.

The WAMAIR Vacuum dust collector range includes a food-grade version whose parts in contact with the dust are certified according to the European regulation. Its design prevents accumulation of residue and makes it easy to clean. In this case, the dust collector is provided with a compliance certificate to the Food Contact Materials Regulation EC 1935/2004.

In case of potentially flammable or explosive materials, a version suitable for use in potentially explosive atmospheres certified according to the ATEX directive can be provided.

Its compact design makes this type of dust collector suitable for applications where limited space is an issue, maintaining efficiency in continuous operation.

Function

WAMAIR Vacuum separates dust particles carried in suspension by an air current using pocket-type filter elements. The dusty air current passes through the filter media, which holds back the dust particles, allowing the clean air to flow through.

WAMAIR Vacuum is designed for pneumatic conveying systems in negative pressure conditions (up to -0.6 bar) meant to safeguard the vacuum pump. However, it can also be used for silo venting.

Features

- Filter surface: 3 ~ 36 m² (32 ~ 387 sq ft)

- Air volume: 150 ~ 4,000 m³/h (88 ~ 2,350 cfm)

- Pocket-type filter elements

- Compressed air pulse-jet cleaning system (5 ~ 6 bar)

- Dust temperature: -20 ~ 80 °C (-4 ~ 176 °F)

- Insertable polygonal casing with cylindrical air outlet

- Tool-free door opening for quick access to filter elements from clean air side

- Hygienic design with comfortable access for cleaning, high-quality surface finishing, welds and packaging

- Multifunctional, multi-voltage electronic control panel

Benefits

- Suitable for applications up to -0.6 bar negative pressure

- FOOD certification EC1935/2004

- ATEX certification

- Low emission level due to WAM filter elements and media (BIA/IFA-certified)

- Wide range of high-quality food-grade filter media

- Compact, sturdy design

- User and maintenance-friendly design

- Captive locking system

- Filter element replacement within a few minutes by one person only

- Multiple voltages meeting different electric specifications

- Worldwide after-sales service and spare parts provided by WAM subsidiaries

Options

- 304 / 316 casing, cover and seal frame

- Glass bead-blasted casing and seal frame

- Advanced electronic control panel with a variety of controls and differential pressure meter (MDPE)

- Pneumatic timer

- Different air outlet positions

- Food-grade version EC1935/2004-certified

- ATEX-version for Zone 22 (Category 3D) or Zone 21 (category 2D) reduced pressure 1 barg

- Suitable for application in internal Zone 20